|

|

|

| |

|

|

|

|

|

|

- (1)

- (2)

- (1)

- (1)

- (5)

- (1)

- (1)

- (1)

- (1)

- (1)

- (1)

|

|

| |

|

|

Build Your Online Product Catalogs?

| Product Name: |

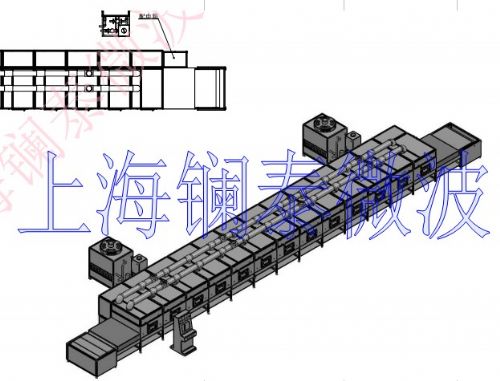

microwave sludge drying equipment

|

| Supply Ability: |

100000USD |

| Related proudcts |

drying equipment, microwave drying, sludge drying, |

| Specifications |

TC-048KW |

| Price Term: |

EXW |

| Port of loading: |

SHANGHAI |

| Minimum Order |

1 |

| Unit Price: |

40000USD |

|

Applies to the desiccation and dehydration of the powder,particle materials. Conventional heatings:such as frame heating ,hot wind heating and steam drying use the heating conduction principle and convey the heat from the outside to the inside,gradually increase the center temperature of the products, that is called external heating.It will take a certain amount of time to get the the desired temperature in the central part .if the heating conduction is poor, then it will take longer to heat the product.it will take long time by these conditional heating methods ,meanwhile, the energy consumption is high and the heating is nonuniform , the labor intensity is high too, the most inconvenient is that the equipment needs to scroll up and down. The characteristic of the microwave drying is that : it can penetrate the interior of an object and heat the inside and the outside simultaneously. The frequency of the electromagnetic oscillation is 2450 MHZ. The mutual friction among the water molecule can generate heat, so at to attain the effect of the heating itself.It can be widely used in the drying and dehydration of chemical products. Such as :Cobalt oxalate, lithium hydroxide, nickel hydroxide, electron magnetic powder, molybdenum powder, mandew, ammonium pericate, lithium cobalt acid, barium cobalt acid, strontium carbonate, etc. After drying ,the moisture content can be reduced from 40% to 0.5% .it only takes 30~45 minutes to dry the products .The drying temperature can control between 80℃~150℃.Microwave chemical drying is a newly high-efficiency, energy-saving and environmental protection technology.

OUR ADVANTAGE

1. The magnetron is equipped with a new type of water-cooled jacket;

2. Transformer oil-return continuous cooling;

3. Magnetron connection tube and transformer connection tube both use copper pipe (to prevent oil leakage );

4. Water and oil circuit using centralized heat transfer cooling (long-term operation temperature of the magnetron does not exceed 55 degrees, the long-term operation temperatu |

| Company: |

Shanghai Lantai Microwave Equipment Manufacture Co. Ltd.

|

| Contact: |

Ms. Helena He |

| Address: |

No.268 RongTian Road RvXiang Town , Jinshan District |

| Postcode: |

201517 |

| Tel: |

862167657286 |

| Fax: |

862167677552 |

| E-mail: |

|

|

|